The Future of Making Things Begins Now

Autodesk Manufacturing Narrative

The only thing that’s changing is everything

We’re living in a time when the speed of change is faster than it’s ever been, and there are no signs of it slowing down. The amount of technological advancement that once occurred over the course of years is now happening in a fraction of that time.

And this too is the case in the world of manufacturing. As technologies continue to accelerate and disrupt, the great differentiator won’t simply be a matter of quality or cost—it will be how much more quickly one company can innovate over another.

Linear is on its last legs

The problem with the traditional product development process—concept to design to manufacture to market to retirement—is product value. It’s fixed. And it’s finite. And it’s no longer good enough.

So in this old world of fixed product values, how do you become more competitive? Use cheaper materials? Improve process efficiency? Sure, and you can reduce your price to compete. But now we’re just talking commodity products. And unfortunately, the kinds of advancements that once created years of competitive separation now will last all of a few weeks. So what can you do?

You can do something else. You can compete on an entirely different level. Instead of slogging along from A to Z, one step after the other, you can be flexible. You can iterate long before you get to the end, long before you create the next generation.

A perfect storm

Technology in its many forms is turning manufacturing on its head. It’s a perfect storm that is radically transforming the way things are designed, made, and used. Across every phase of the product development process, you have the opportunity to one up your competitor with an iterative and agile approach to product development.

Concept

If you can customize or configure a product to better meet the needs of your customers, in their eyes, that means you care about what they want. There’s no better advantage than that.

Design

Innovative thinking is not geographically bound. But you are. Design is about collaboration, and the ability of people to work on the same project at the same time from another building or another country is invaluable.

Produce

Traditional limitations of economies of scale are being set aside—think batch-run of one–opening the door for new manufacturing methods. Additive manufacturing and configurable factories will be the new norm.

Sell

It’s time to move beyond the boundaries of fixed product value, beyond the point of sale. And while powerful, it has to be more than just creating personalized products. The next big battle with your competitor will be around creating personalized experiences. Connected services enable you to layer in additional services for your customers. It’s about providing more value with the products you’re bringing to market. It’s about product as a service.

Repeat

What all this ultimately means is that you can extract a greater lifetime value from the products you produce. And here’s the real beauty…once you can connect to your product in the field—where your product will provide you with usage data—you can bring that information back into the development process and make that product better.

This is your truly iterative and agile development process. This is what gives you your competitive advantage. This is the future of making things.

Sounds great. Now what?

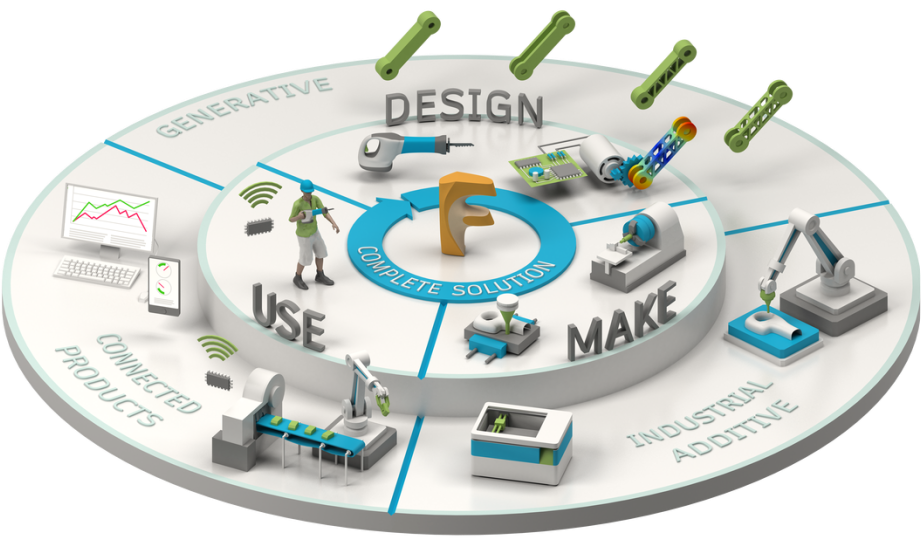

The future of making things is here, and the Autodesk product innovation platform, Fusion, helps you take advantage of the opportunities being generated by these technological leaps by uniting every stage of the product development lifecycle on a single technology platform.

Fusion is one of the first cloud-connected product innovation platforms in the manufacturing industry, and what sets it apart, what will help set you apart, is its integrated set of cloud applications developed specifically for the ways in which products will be designed, made, and used.

Advantage, you

With Fusion you can extend your competitive advantage in four critical areas:

Integration

A truly integrated solution, Fusion unites the entire development process into a single platform using your data and utilizes the always-connected, always accessible ecosystem of the cloud. From data and lifecycle management, collaboration, industrial styling, and mechanical engineering to parametrics, drawings, visualization, simulation, machining, additive manufacturing, and IoT it’s all there in one place.

Design

Autodesk is at the forefront of Generative Design, a software technology that will be incorporated into the Fusion platform. Generative Design enables the creation of highly optimized designs that meet predetermined goals and constraints. Employing evolutionary algorithms, machine learning, shape synthesis, and multi-physics, the software generates thousands of design options for a single idea—many of which impossible for humans to have created.

Make

Now that you’re designing optimized products, you need advanced manufacturing methods and materials to create them. Large-scale on-demand manufacturing and local 3D printing is quickly becoming a reality. New materials and integrated additive and subtractive methods are making previously impossible designs possible and significantly reducing manufacturing waste. Manufacturing facilities will become more connected, collecting real-time data and using it to streamline processes and identify problems before they arise.

Which is why Autodesk is integrating manufacturing solutions into Fusion, the evolution of 3D printing into large-scale manufacturing, which employs new machines and the growing field of materials science. Autodesk is creating tools to enable the design, optimization, simulation, and building of parts in metals and plastics using SLA, SLM, DLP, and FDM machines.

Use

Your optimized products are now being manufactured in a whole new way, a

way that streamlines, reduces waste, and saves time and money. But you’re

not done. You want your products to be better. Fusion’s connected products

capabilities capture, analyze, and manage real-world performance data that

you can incorporate directly into your next design, closing the development

loop. This isn’t guesswork. It’s iterative insight that increases lifetime value.

But you were born to build

This new way of working with Fusion sounds wonderful, but what if you

need more? What if you want to develop your own data, apps, experiences,

and services for this new era?

Meet Forge, a set of cloud services, APIs, and SDKs to enable you to do just

that. From design, visualization, and reality capture to collaboration, 3D

printing, and IoT solutions, Forge provides the perfect platform on which to

build your own future of making things.

To succeed, strike a balance

Over time, your primary source of revenue will shift from the products you

make and sell today to those that are designed and built in all new ways.

Your next generation.

To support that change, you need to maintain the health of your business in

the short term by tapping the full potential of your existing products. So

continue using the tools you know and love today to iterate on your current

offerings. But when you start working on your next generation, make sure

you’re using the right solution to help you achieve your ultimate

competitive advantage. That solution is the product innovation platform,

your admission to the future of making things.

Autodesk Manufacturing Narrative

The only thing that’s changing is everything

We’re living in a time when the speed of change is faster than it’s ever been, and there are no signs of it slowing down. The amount of technological advancement that once occurred over the course of years is now happening in a fraction of that time.

And this too is the case in the world of manufacturing. As technologies continue to accelerate and disrupt, the great differentiator won’t simply be a matter of quality or cost—it will be how much more quickly one company can innovate over another.

Linear is on its last legs

The problem with the traditional product development process—concept to design to manufacture to market to retirement—is product value. It’s fixed. And it’s finite. And it’s no longer good enough.

So in this old world of fixed product values, how do you become more competitive? Use cheaper materials? Improve process efficiency? Sure, and you can reduce your price to compete. But now we’re just talking commodity products. And unfortunately, the kinds of advancements that once created years of competitive separation now will last all of a few weeks. So what can you do?

You can do something else. You can compete on an entirely different level. Instead of slogging along from A to Z, one step after the other, you can be flexible. You can iterate long before you get to the end, long before you create the next generation.

A perfect storm

Technology in its many forms is turning manufacturing on its head. It’s a perfect storm that is radically transforming the way things are designed, made, and used. Across every phase of the product development process, you have the opportunity to one up your competitor with an iterative and agile approach to product development.

Concept

If you can customize or configure a product to better meet the needs of your customers, in their eyes, that means you care about what they want. There’s no better advantage than that.

Design

Innovative thinking is not geographically bound. But you are. Design is about collaboration, and the ability of people to work on the same project at the same time from another building or another country is invaluable.

Produce

Traditional limitations of economies of scale are being set aside—think batch-run of one–opening the door for new manufacturing methods. Additive manufacturing and configurable factories will be the new norm.

Sell

It’s time to move beyond the boundaries of fixed product value, beyond the point of sale. And while powerful, it has to be more than just creating personalized products. The next big battle with your competitor will be around creating personalized experiences. Connected services enable you to layer in additional services for your customers. It’s about providing more value with the products you’re bringing to market. It’s about product as a service.

Repeat

What all this ultimately means is that you can extract a greater lifetime value from the products you produce. And here’s the real beauty…once you can connect to your product in the field—where your product will provide you with usage data—you can bring that information back into the development process and make that product better.

This is your truly iterative and agile development process. This is what gives you your competitive advantage. This is the future of making things.

Sounds great. Now what?

The future of making things is here, and the Autodesk product innovation platform, Fusion, helps you take advantage of the opportunities being generated by these technological leaps by uniting every stage of the product development lifecycle on a single technology platform.

Fusion is one of the first cloud-connected product innovation platforms in the manufacturing industry, and what sets it apart, what will help set you apart, is its integrated set of cloud applications developed specifically for the ways in which products will be designed, made, and used.

Advantage, you

With Fusion you can extend your competitive advantage in four critical areas:

Integration

A truly integrated solution, Fusion unites the entire development process into a single platform using your data and utilizes the always-connected, always accessible ecosystem of the cloud. From data and lifecycle management, collaboration, industrial styling, and mechanical engineering to parametrics, drawings, visualization, simulation, machining, additive manufacturing, and IoT it’s all there in one place.

Design

Autodesk is at the forefront of Generative Design, a software technology that will be incorporated into the Fusion platform. Generative Design enables the creation of highly optimized designs that meet predetermined goals and constraints. Employing evolutionary algorithms, machine learning, shape synthesis, and multi-physics, the software generates thousands of design options for a single idea—many of which impossible for humans to have created.

Make

Now that you’re designing optimized products, you need advanced manufacturing methods and materials to create them. Large-scale on-demand manufacturing and local 3D printing is quickly becoming a reality. New materials and integrated additive and subtractive methods are making previously impossible designs possible and significantly reducing manufacturing waste. Manufacturing facilities will become more connected, collecting real-time data and using it to streamline processes and identify problems before they arise.

Which is why Autodesk is integrating manufacturing solutions into Fusion, the evolution of 3D printing into large-scale manufacturing, which employs new machines and the growing field of materials science. Autodesk is creating tools to enable the design, optimization, simulation, and building of parts in metals and plastics using SLA, SLM, DLP, and FDM machines.

Use

Your optimized products are now being manufactured in a whole new way, a

way that streamlines, reduces waste, and saves time and money. But you’re

not done. You want your products to be better. Fusion’s connected products

capabilities capture, analyze, and manage real-world performance data that

you can incorporate directly into your next design, closing the development

loop. This isn’t guesswork. It’s iterative insight that increases lifetime value.

But you were born to build

This new way of working with Fusion sounds wonderful, but what if you

need more? What if you want to develop your own data, apps, experiences,

and services for this new era?

Meet Forge, a set of cloud services, APIs, and SDKs to enable you to do just

that. From design, visualization, and reality capture to collaboration, 3D

printing, and IoT solutions, Forge provides the perfect platform on which to

build your own future of making things.

To succeed, strike a balance

Over time, your primary source of revenue will shift from the products you

make and sell today to those that are designed and built in all new ways.

Your next generation.

To support that change, you need to maintain the health of your business in

the short term by tapping the full potential of your existing products. So

continue using the tools you know and love today to iterate on your current

offerings. But when you start working on your next generation, make sure

you’re using the right solution to help you achieve your ultimate

competitive advantage. That solution is the product innovation platform,

your admission to the future of making things.

https://autodeskchannel.gosavo.com/CustomPage/View.aspx?id=36523947